High-tech production

for high-end demands

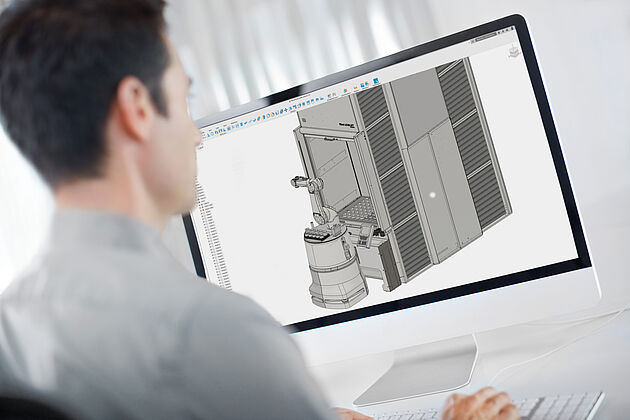

The linchpin of the production facility is the modern storeroom for sheet metal pieces which is situated centrally in the plant. From here the unworked metal sheets and also sub-assemblies are fed automatically to the machining centers and then returned to buffer storage.

The punching and laser work on the sheet metal pieces needed for production is carried out on TruMatic and TruPunch machines from the company TRUMPF. Automatic loading systems are available to feed the machines.

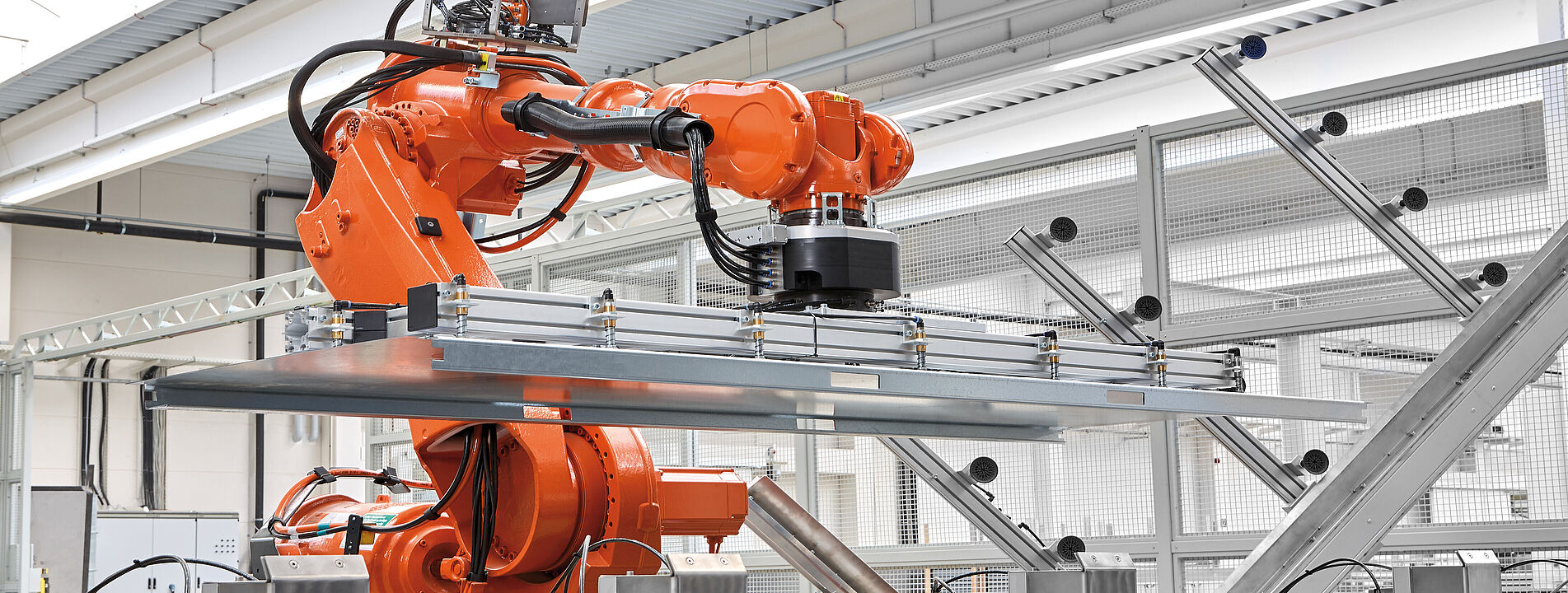

In order to guarantee the consistently high quality of Hänel products, state-of-the-art welding procedures are carried out by fully automated precision robots in a welding center developed specially for Hänel.

To ensure we can produce the high numbers of containers required, we use high-efficiency bending machines with robot technology.

Responsibility for the environment

It goes without saying that production at our three plants meets the latest environmental guidelines and even exceeds them. Only environmentally friendly, recyclable materials are used.